tungsten carbide corrugated container cutter

Key words:

hard metal

Classification:

Products

Disc cutter

- 产品描述

-

- Commodity name: tungsten carbide corrugated container cutter

- Commodity ID: 1310963813846765568

Our blades are used for corrugated carton slitter scorer machine,cardboard slotting machine,carton printing machine etc.They can be made by tungsten carbide with long life working time.We have all standard size and also can customized as customers' requirements.

Tungsten Carbide Corrugated Cardboard cutter

Our blades are used for corrugated carton slitter scorer machine,cardboard slotting machine,carton printing machine etc.They can be made by tungsten carbide with long life working time.We have all standard size and also can customized as customers' requirements.

In addition,we can provide the grinding wheel for the blade,slotting blade and others blade used for carton ,tobacco machinery.

material grade :

Grade Grain size (um) Cobalt content (100%) Density (g/cm3) Hardness (HRA) T.R.S (N/mm2) YG6X 0.8-1.2 6 14.8 91 2000 YG10X 0.8-1.2 10 14.42 91.8 4000 YG12X 0.8-1.2 12 14.5 89.5 2600 Material grade Tungsten Carbide YG10X, YG13X, OEM Thickness 0.2-6mm or customized Flatness 0.003mm Type of edge single edge, double edge HRA 85-93 Straightness <0.1 Surface roughness Ra0.2 Laser engraving Done as requirement Package 4 pcs/set,Simple packing/Plastic box packing/Blister packing Main Size OD(mm) ID(mm) Thickness(mm) Cutting Edge 300 112 1.4 double 280 168 1.4 double 265 112 1.3 double 260 168 1.4 double 260 140 1.4 double 240 132 1.2 double 230 110 1.3 double 140 46 0.5 single 100 16 0.3 single 85 16 0.25 single 60 19 0.27 single Size Can be customized according to customer requirements Advantages 1, High quality raw materials. 2. Durable & Long service life. 3. High precision. 4. Nice and solid packaging. 5. Excellent weather resistance and waterproof. Application For paperboard/paper/cardboard/carton/Tobacco machine to cut. Products Show:

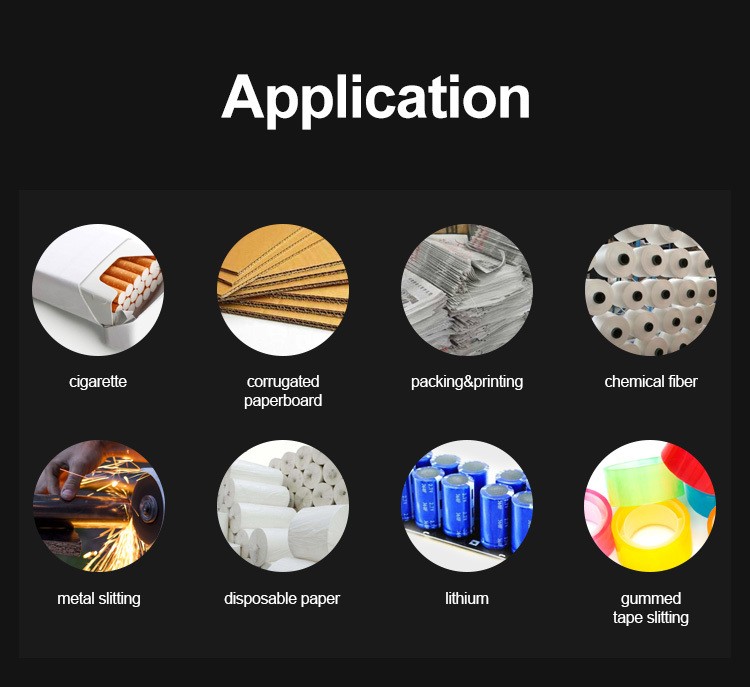

- The carbide circular blades for Slitting Corrugated Board, carbide rotary blade for rubbers cutting, carbide blade for battery industry, carbide blades for Tobacco Machines, carbide circuit board cutting knife,

- carbide blades for metal cutting, carbide knife for Rewinder machines, carbide blades for chemical fiber cutting, carbide blades for printing industry, carbide milling cutter for paper industry, and carbide blades for other special range.

Production process:

1. Ballmilled: To make the powder to be mixed evenly.

2. Spray drying: To make the powder into a superior homogeneous

partical size, and with good flowability. So the dimension viriation on the sintered blank is much smaller.

3. Heavy duty pressing: Guaranteed that the product can be pressed and moulded at one time. And could offer

a tighter tolerance control, which ensures the higher performance of the products.

4. HIP sintering: Gives the carbide blank maximum toughness. Carbide blanks are sintered at a temperature around

1400 degree which could make the carbide super hard and tough.

Key words:- Tungsten Carbide Corrugated Cardboard cutter

- carbide round cutter

- paper cutter

Previous Page

Next Page

Previous Page

Next Page

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!