Hot sale factory prices customized tungsten plate

High Hardness Tungsten carbide plate for cutting tool

tungsten carbide thin plates used to make metal and wood cutters: Tungsten carbide finished plate with high hardness, high wear resistance, high T.R.S. and toughness, heat resistance, corrosion resistance and a series of excellent performance, especially the high hardness and wear resistance,even if the temperature at 500 degrees also remained unchanged.

Key words:

hard metal

Classification:

Plates

- 产品描述

-

- Commodity name: Hot sale factory prices customized tungsten plate

- Commodity ID: 1310963735908208640

High Hardness Tungsten carbide plate for cutting tool tungsten carbide thin plates used to make metal and wood cutters: Tungsten carbide finished plate with high hardness, high wear resistance, high T.R.S. and toughness, heat resistance, corrosion resistance and a series of excellent performance, especially the high hardness and wear resistance,even if the temperature at 500 degrees also remained unchanged.

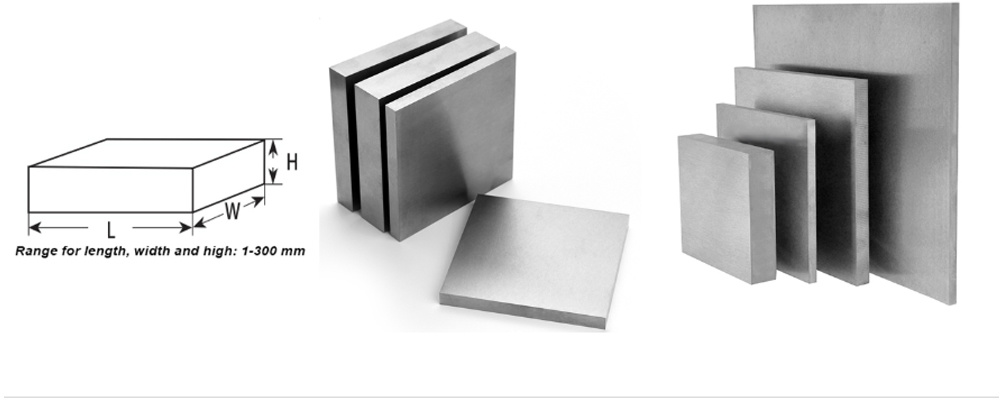

Introduction description of tungsten carbide plates:Material: 100% virgin raw material with submicron and average grain sizeTolerance: strict tolerance extent control, which can reach ±0.01mmGrades: various for choice: YG6, YG8, YG8C, YG11C, YG15CTypes: standard, conical, parabolic, ballisticPhysical performance: high hardness and impact toughness, very good mechanical and chemical stabilityCustomized hard metal carbide platesAdvantage:

Introduction description of tungsten carbide plates:Material: 100% virgin raw material with submicron and average grain sizeTolerance: strict tolerance extent control, which can reach ±0.01mmGrades: various for choice: YG6, YG8, YG8C, YG11C, YG15CTypes: standard, conical, parabolic, ballisticPhysical performance: high hardness and impact toughness, very good mechanical and chemical stabilityCustomized hard metal carbide platesAdvantage:

1. Easy brazing

2. High wear resistance and toughness

3. High hardness and precision

4. With HIP sintering

5. Used for making the woodworking tools, TCT router bits

Application:tungsten carbide plates usually used for general wood cutters/hard wood cutters, plastic and tobacco cutting

Production in a range of woodworking tools, plane, hop cutter, sub-cutter

Our company use advanced molding process in order to produce various of plates to meet clients requirements。

Material grade of tungsten carbide plates Grade Density g/cm3 Hardnes HRA T.R.S Mpa Performance&application recommended HY6A 14.85 92.5 2000 Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,

wear-resistant parts etc.HY8 14.7 89.8 2800 High bending strength,wear resistance lower than YG6A, suitable for manufacturing

cutter ,wear-resistant parts etc.HY11 14.4 88.5 2900 High bending strength,wear resistance lower than YG6A, suitable for manufacturing

cutter ,wear-resistant parts etc.HY15 14 87 3000 Suitable for manufacturing punching dies, wear-resistant parts. HY20 13.5 85.5 2800 High bending strength,suitable for manufacturing progressive dies and other

punching dies.HY25 13.1 81.5 2950 High bending strength,wear resistance lower than YM6A, suitable for manufacturing

cutter ,wear-resistant parts etc.HY2T 14.25 92 2500 Fine grain alloy, with high wear resistance, bending strength, bonding resistance

and thermal strength. it is suitable for machining refractory alloys,stainless steel,

high manganese steel, etc.It is very important to select the right grade to match the using purpose, we have to consider the physical properties of the processing object, also the working

condition for tools, like running speed, impact. Other grades can be offered as per customers'requirements.Size of tungsten carbide plates length(mm)(tol.±2.2) wide(mm)(tol.±2.2) thickness(mm)(tol.±0.35) 50 50 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 70 70 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 100 50 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 100 100 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 100 120 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 100 150 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 105 105 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 125 150 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 150 200 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 200 250 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. 300 300 1, 2.15, 2.5, 3, 3.5 , 4, 4.5, 5, 5.5, 6…. Key words:- Hot sale factory prices customized tungsten plate

- Share to YG8/K20 Carbide Plates

- carbide polished plate mould plate

Previous Page

Previous Page

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!