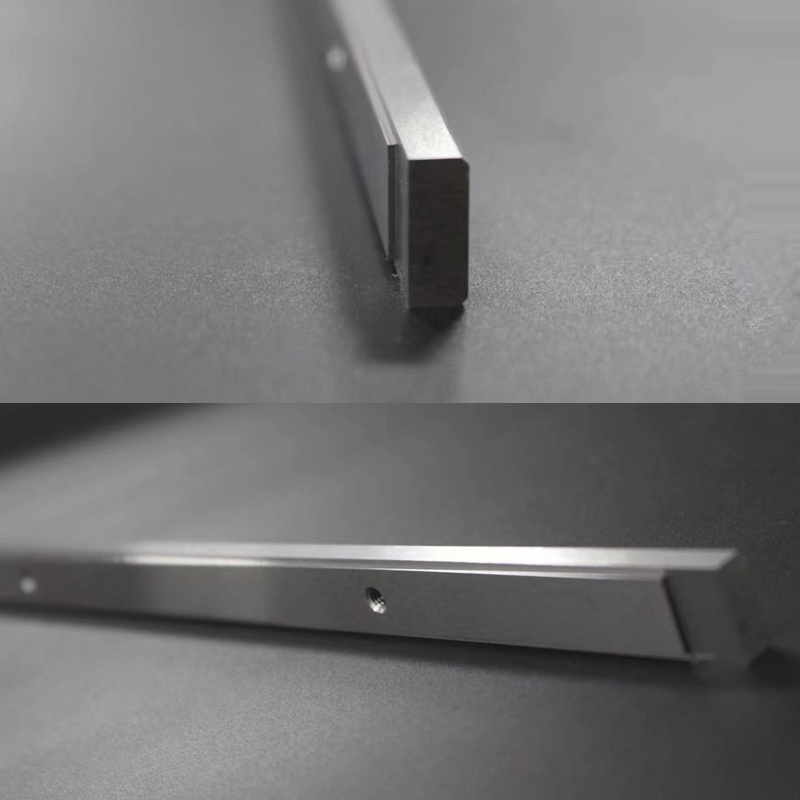

customization tungsten carbide with perforated strip blade

Tungsten carbide strips widely known as one kind of carbide cutting tools, it’s available for different grinding geometric parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts semi-automatic lathe,automatic lathe and planning machine to work groovesand operate cutting, etc.

Key words:

hard metal

Classification:

Strips

- 产品描述

-

- Commodity name: customization tungsten carbide with perforated strip blade

- Commodity ID: 1310963722536767488

Tungsten carbide strips widely known as one kind of carbide cutting tools, it’s available for different grinding geometric parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts semi-automatic lathe,automatic lathe and planning machine to work groovesand operate cutting, etc.

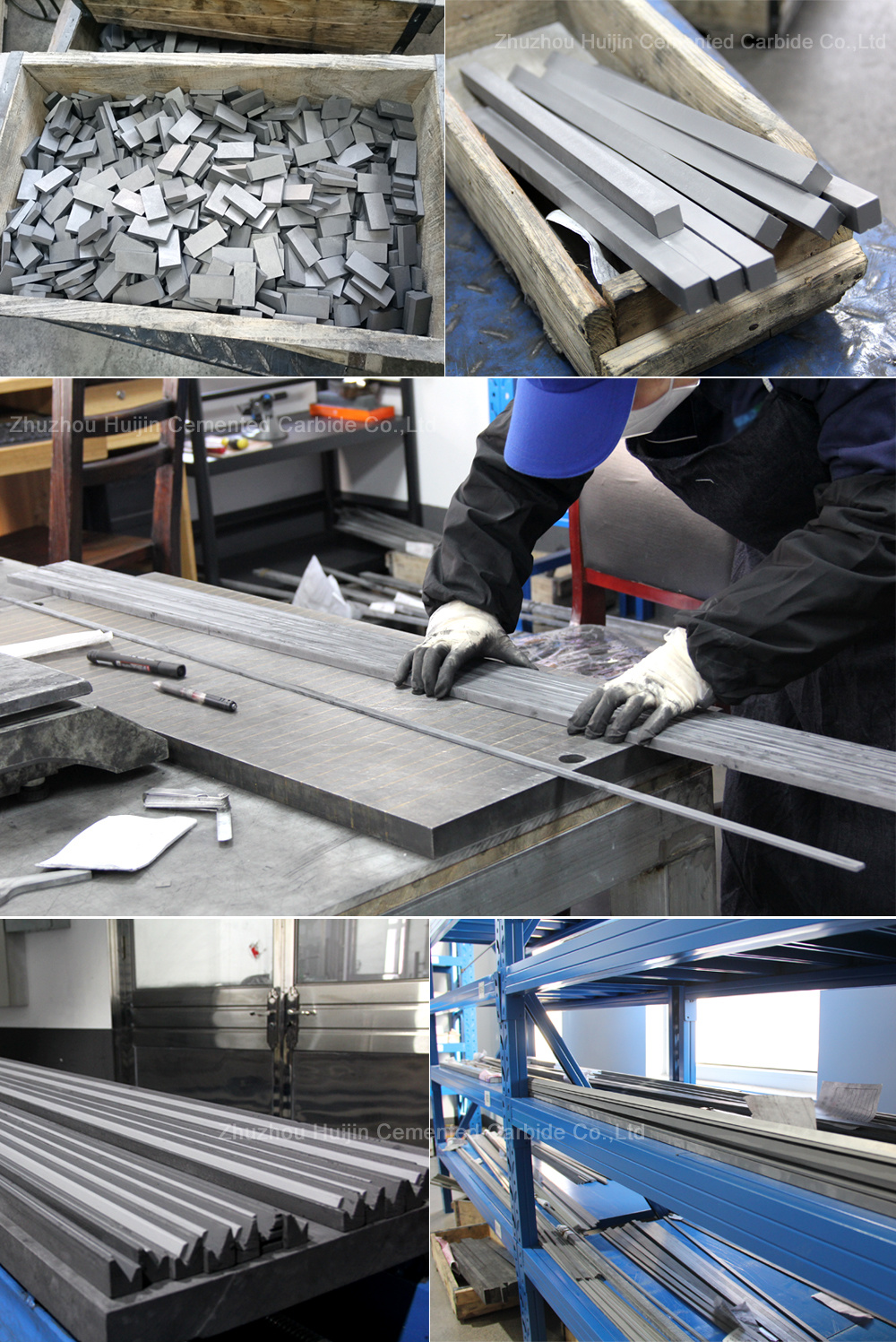

Tungsten carbide strips are also known as rectangular tungsten carbide rods, tungsten carbide flats, and tungsten carbide flat bars are sintered metallurgical products of powder form. It is manufactured in vacuum or Hydrogen reduction furnaces with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni), or Molybdenum (Mo) as the binder.Product feature:1.Easy to be brazed, good wear resistance and toughness.2 Untrafine grain size raw material to keep excellent strength and hardness.3.Both standard sizes and customizes sizes are available.4. 100% use virgin raw materials, our constant is quality in every order we produce, large or small5. Both blank and finely ground are available.

Tungsten carbide strips are also known as rectangular tungsten carbide rods, tungsten carbide flats, and tungsten carbide flat bars are sintered metallurgical products of powder form. It is manufactured in vacuum or Hydrogen reduction furnaces with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni), or Molybdenum (Mo) as the binder.Product feature:1.Easy to be brazed, good wear resistance and toughness.2 Untrafine grain size raw material to keep excellent strength and hardness.3.Both standard sizes and customizes sizes are available.4. 100% use virgin raw materials, our constant is quality in every order we produce, large or small5. Both blank and finely ground are available.

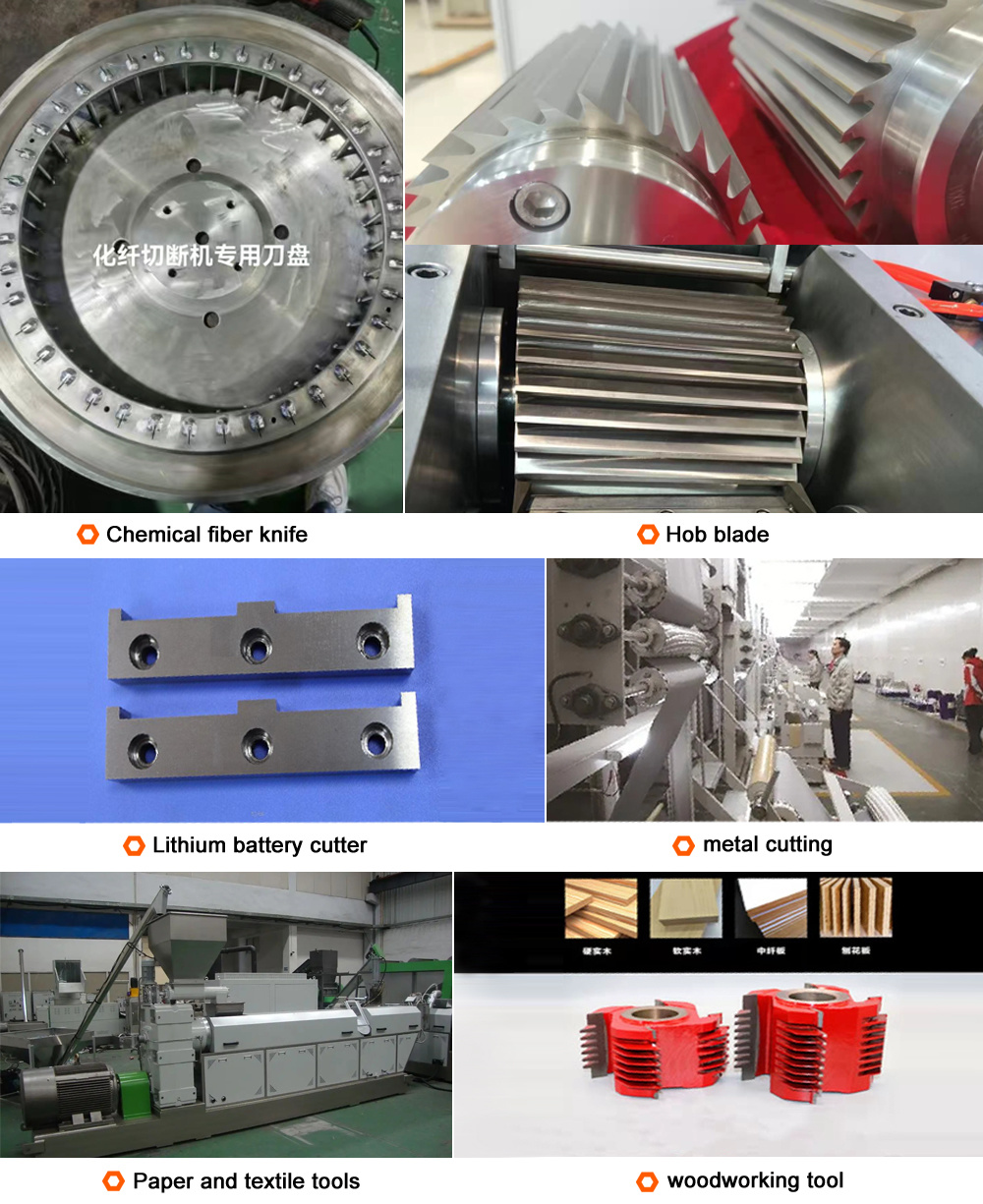

1.We are a professional tungsten carbide manufacturer in Zhuzhou City over 10 years and have a few senior engineerswho specializes in tungsten carbide field for many decades;2.Recommended grade: YG6(K10) YG6X YG8(K20) YG15(K30), we can research and develop more suitable formulaaccording to use condition and processing characteristics for client.3.For your non-standard parts, we have strong ability to make mold by ourselves, and produce them per your requirements.4.We have strict quality control and assurance system to guarantee the consistent quality.Application of Carbide strips:Paper crosscutting knife (corrugated paper, wet and dry paper towels, packaging, printing, paper industry, etc.) Cut copper foil, aluminum foil and other metal foil Cutting leather rubber, hardware tools, processing textile, chemical fiber, buttons, animal husbandry tools, food processing tools so on.

1.We are a professional tungsten carbide manufacturer in Zhuzhou City over 10 years and have a few senior engineerswho specializes in tungsten carbide field for many decades;2.Recommended grade: YG6(K10) YG6X YG8(K20) YG15(K30), we can research and develop more suitable formulaaccording to use condition and processing characteristics for client.3.For your non-standard parts, we have strong ability to make mold by ourselves, and produce them per your requirements.4.We have strict quality control and assurance system to guarantee the consistent quality.Application of Carbide strips:Paper crosscutting knife (corrugated paper, wet and dry paper towels, packaging, printing, paper industry, etc.) Cut copper foil, aluminum foil and other metal foil Cutting leather rubber, hardware tools, processing textile, chemical fiber, buttons, animal husbandry tools, food processing tools so on.

Grade Density

(g/cm3)Hardness

(HRA)T.R.S

MPaPerformance & spplication recommended HY6 14.9 90.5 2400 Good wear resistance,suitable for machining hard wood,raw wood,aluminum section bar,brass rod and cast iron. HY6A 14.85 92.5 2000 Wear resistance higher than HY6,suitable for machining hard wood,raw wood,aluminum section bar,brass rod and cast iron. HY8 14.7 89.8 2800 High wear and impact resistance,suitable for machining dry wood,soft wood and non-ferrous metal section bar. HY2T 14.25 92.0 2400 Fine grain alloy,with high wear resistance,bending strength,bonding resistance and thermal strength.

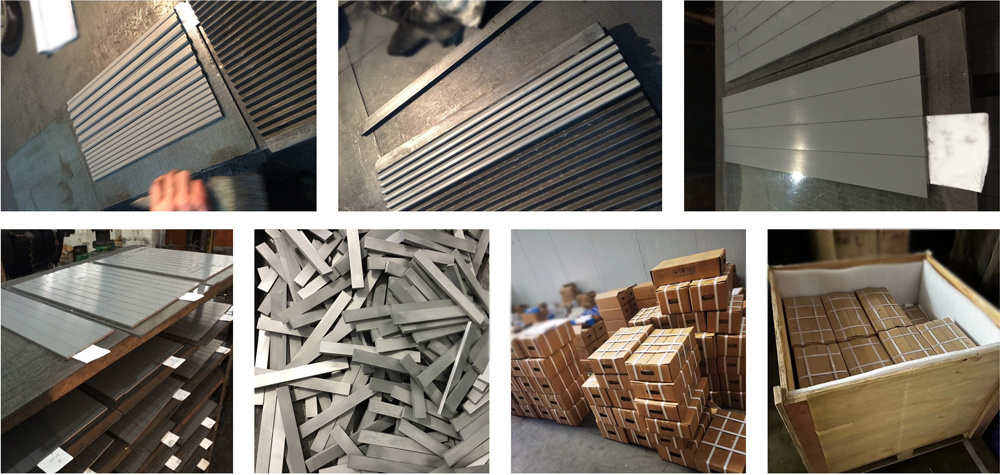

lt is suitable for machining refractory alloys,stainless steel,high manganese steel,etcHS25 13.0 91.0 2200 Wear resistance and strength comparatively higher,suitable for machining cast iron,non-ferrous metal and non-metallid materials HY10 14.45 91.8 3000 Wear resistance and strength comparatively higher,suitable for machining cast iron,non-ferrous metal and non- metallid materials Size of carbide strips W(mm) T(mm) L(mm) W(mm) T(mm) L(mm) W(mm) T(mm) L(mm) 3.5 1~3.5 100~330 14 1~14 100~330 26 1~26 100~1000 4 1~4 100~330 15 1~15 100~330 27 1~27 100~1000 4.5 1~4.5 100~330 16 1~16 100~330 28 1~28 100~1000 5 1~5 100~330 17 1~17 100~330 30 1~30 100~1000 5.5 1~5.5 100~330 18 1~18 100~330 32 1~30 100~1000 6 1~6 100~330 19 1~19 100~330 35 1~30 100~1000 7 1~7 100~330 20 1~20 100~1000 36 1~30 100~1000 8 1~8 100~330 21 1~21 100~1000 40 1~30 100~1000 9 1~9 100~330 22 1~22 100~1000 45 1~30 100~1000 10 1~10 100~330 23 1~23 100~1000 48 1~30 100~1000 11 1~11 100~330 24 1~24 100~1000 50 1~30 100~1000 12 1~12 100~330 25 1~25 100~1000 60 1~30 100~1000 We provide a wide range of squared and flat Carbide Strips in different dimensions, minimum 1.0 mm thickness lengthup to 2300mm. Width up to 60mm. We can also provide fine grinding strips according to the customer's requirements, and the tolerance can reach ± 0.05mm. Professional precision machining:There are many kinds of machining methods for carbide precision machining. Such as EDM, slow wire cutting, CNC milling,CNC lathe processing,etc.Our company is a professional manufacturer of cemented carbide integrating production and precisionmachining. The company has advanced production and processing equipment such as turning and milling compound machining center,five-axis machining center, four-axis vertical machining center, CNC horizontal boring and milling machine, deep hole drilling,boring and honing, vacuum sintering furnace, wire cutting, etc. Processing supporting capacity. It has very strong strength in theprecision machining of cemented carbide, and is equipped with various advanced machining equipment, which is suitable for themachining of various high-precision, special materials, eccentric inner shape, elbows, and complex geometric parts.product packaging:

Professional precision machining:There are many kinds of machining methods for carbide precision machining. Such as EDM, slow wire cutting, CNC milling,CNC lathe processing,etc.Our company is a professional manufacturer of cemented carbide integrating production and precisionmachining. The company has advanced production and processing equipment such as turning and milling compound machining center,five-axis machining center, four-axis vertical machining center, CNC horizontal boring and milling machine, deep hole drilling,boring and honing, vacuum sintering furnace, wire cutting, etc. Processing supporting capacity. It has very strong strength in theprecision machining of cemented carbide, and is equipped with various advanced machining equipment, which is suitable for themachining of various high-precision, special materials, eccentric inner shape, elbows, and complex geometric parts.product packaging: Key words:

Key words:- tungsten carbide 7-shaped strip Cutting metal products

- tungsten carbide 7-shaped strip Cutting metal products

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!