Tungsten carbide stud for HPGR

Key words:

hard metal

Classification:

Tungsten carbide stud for HPGR

- 产品描述

-

- Commodity name: Tungsten carbide stud for HPGR

- Commodity ID: 1310963840023416832

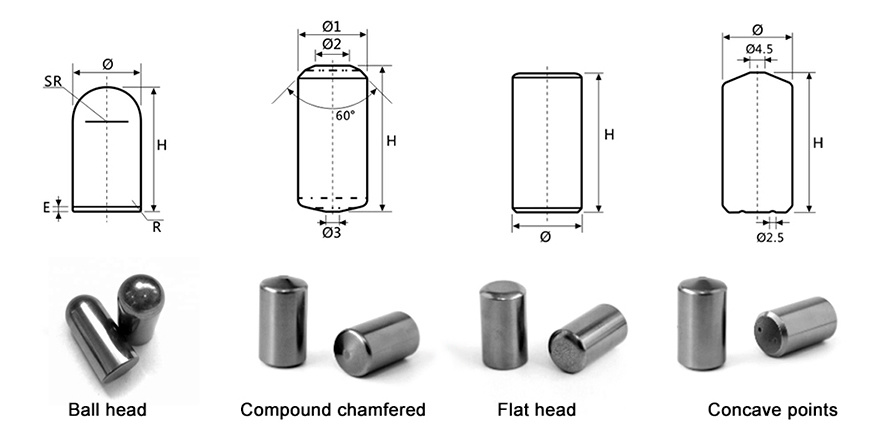

Tungsten Carbide Stud for HPGR Application range of cemented carbide studs Application range of cemented carbide tungsten steel column nails: mainly used for crushing by roller presses. The roller press is a high-efficiency crushing equipment, and the roller sleeve of the roller press is the core consumption component of key equipment such as cement, mining, thermal power, and coal chemical industry. Its performance directly determines the output benefit of the production line. As the core accessories of the roller press, the stud provides high wear resistance and high compressive strength for the roller press, which can meet the requirements of different working conditions. Carbide studs for roller presses have good wear resistance and compressive strength, and are widely used in the crushing of cement clinker, limestone, bauxite, iron ore and other operational requirements, with high work efficiency.The service life of the stud is more than 8,000 to 10,000 hours. Size(Specification:) of cemented carbide studs: Roller presses are widely used, and to deal with crushing different materials, cemented carbide column nails should also choose corresponding models: ball-shaped tungsten steel nails, compound chamfered tungsten steel nails, flat-headed tungsten steel nails, with concave points Studs. Carbide studs for roller press have high hardness, high strength and good impact resistance, which can greatly improve the service life and work efficiency of the roller press. *We can also develop different models and sizes according to the actual needs of customers. Product grade recommendation: Grade Physical Properties Chemical Composition(%) Hardness Bending Strength Density Coercivity Cobalt Carbon (HRA) (>=N/mm²) (g/cm³) (kA/m) YG15C 85.0~86.5 2500 13.90~14.10 4.5~6.5 14.7~15.3 4.90~5.50 YG20 86.0~87.5 2450 13.40~13.60 8.0~11.0 19.7~20.4 4.50~4.80 YG15 87.0~88.5 2800 13.95~14.15 7.0~10.0 14.1~14.8 4.95~5.60 HJ15 87.8~90.0 2950 13.95~14.15 8.0~10.5 14.5~14.9 ----- HJ20 85.8~87.2 2600 13.87~14.17 5.8~8.0 14.8~15.2 -----

As the core accessories of the roller press, the stud provides high wear resistance and high compressive strength for the roller press, which can meet the requirements of different working conditions.

As the core accessories of the roller press, the stud provides high wear resistance and high compressive strength for the roller press, which can meet the requirements of different working conditions.

Carbide studs for roller presses have good wear resistance and compressive strength, and are widely used in the crushing of cement clinker, limestone, bauxite, iron ore and other operational requirements, with high work efficiency.The service life of the stud is more than 8,000 to 10,000 hours.Size(Specification:) of cemented carbide studs:Roller presses are widely used, and to deal with crushing different materials, cemented carbide column nails should also choose corresponding models: ball-shaped tungsten steel nails, compound chamfered tungsten steel nails, flat-headed tungsten steel nails, with concave points Studs. Carbide studs for roller press have high hardness, high strength and good impact resistance, which can greatly improve the service life and work efficiency of the roller press.

Grade Physical Properties Chemical Composition(%) Hardness Bending Strength Density Coercivity Cobalt Carbon (HRA) (>=N/mm²) (g/cm³) (kA/m) YG15C 85.0~86.5 2500 13.90~14.10 4.5~6.5 14.7~15.3 4.90~5.50 YG20 86.0~87.5 2450 13.40~13.60 8.0~11.0 19.7~20.4 4.50~4.80 YG15 87.0~88.5 2800 13.95~14.15 7.0~10.0 14.1~14.8 4.95~5.60 HJ15 87.8~90.0 2950 13.95~14.15 8.0~10.5 14.5~14.9 ----- HJ20 85.8~87.2 2600 13.87~14.17 5.8~8.0 14.8~15.2 ----- *We can also develop different models and sizes according to the actual needs of customers.Application range of cemented carbide studs :Application range of cemented carbide tungsten steel column nails: mainly used for crushing by roller presses.

The roller press is a high-efficiency crushing equipment, and the roller sleeve of the roller press is the core consumption component of key equipment such as cement, mining, thermal power, and coal chemical industry. Its performance directly determines the output benefit of the production line.

Key words:

Key words:- Tungsten carbide stud for HPGR

Previous Page

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!