Tungsten carbide flat sealing ring

Key words:

hard metal

Classification:

Sealing ring

- 产品描述

-

- Commodity name: Tungsten carbide flat sealing ring

- Commodity ID: 1310963820217913344

We are manufacturing Cemented Tungsten Carbide Wear Parts for use Oil & Gas Industry. Aseeder Cemented tungsten carbide wear parts are available in a wide range of styles and size combinations for Petroleum industry.

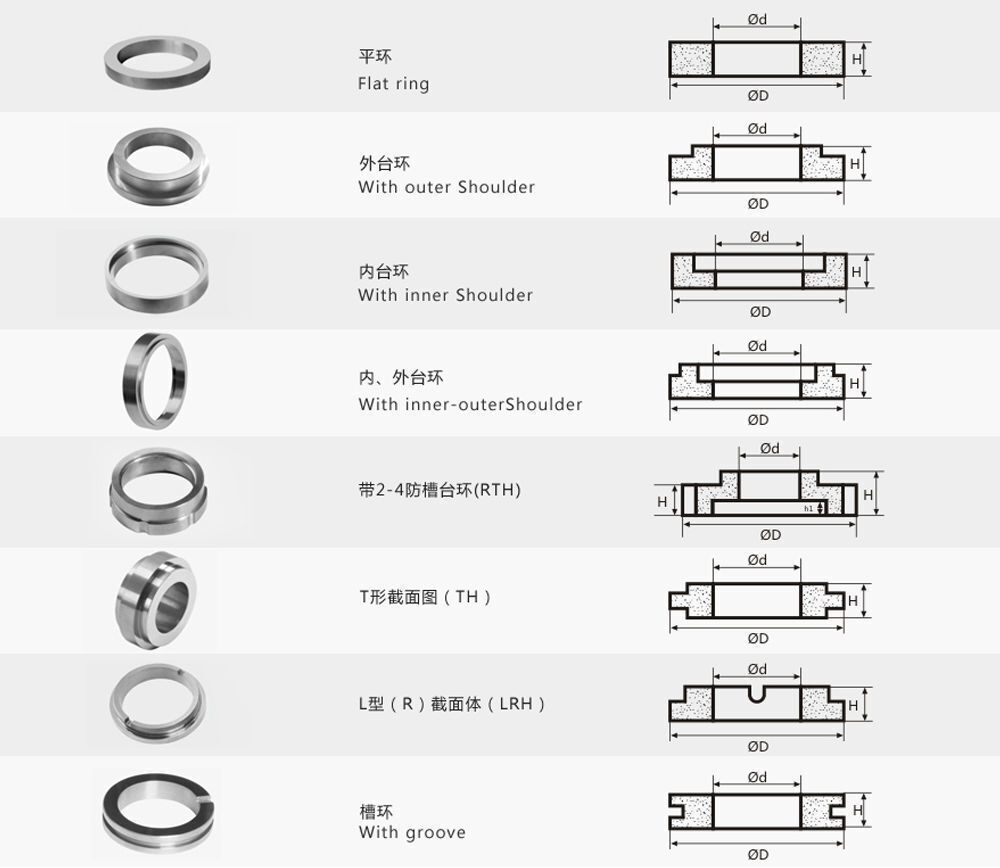

With high strength, toughness, wear and corrosion resistance and excellent heat-conducting property, hard alloy sealing rings provided by Zhuzhou huijin carbide are mainly applied in some places with terrible environment. Zhuzhou Huijin carbide designs different marks according to different environment; the products can be divided into inlaid hard alloy stationary ring and solid carbide stationary ring according to the structure, such as different types with/without anti-rotating pins. Refer to product catalog for details. The ordinary marks of hard alloy sealing rings produced by the company as follows:Mechanical seal ring are used to seal the clearance between the rotating shaft and the stationary housing in equipment such as pumps and mixers, so that liquid can not leak out through this clearance.Tungsten carbide is the most excellent seal face material in the seal material world.One of main reasons for using Tungsten Carbide is the additional wear resistance that can be achieved in both moving and static parts.This is particular the case in serve service conditions, such as high temperature,and high levels of corrosion and abrasion.It is widely used in Oil Refineries, petrochemical industries, Fertilizer Plants,Petrochemical plants, Pharmaceutical industries.

With high strength, toughness, wear and corrosion resistance and excellent heat-conducting property, hard alloy sealing rings provided by Zhuzhou huijin carbide are mainly applied in some places with terrible environment. Zhuzhou Huijin carbide designs different marks according to different environment; the products can be divided into inlaid hard alloy stationary ring and solid carbide stationary ring according to the structure, such as different types with/without anti-rotating pins. Refer to product catalog for details. The ordinary marks of hard alloy sealing rings produced by the company as follows:Mechanical seal ring are used to seal the clearance between the rotating shaft and the stationary housing in equipment such as pumps and mixers, so that liquid can not leak out through this clearance.Tungsten carbide is the most excellent seal face material in the seal material world.One of main reasons for using Tungsten Carbide is the additional wear resistance that can be achieved in both moving and static parts.This is particular the case in serve service conditions, such as high temperature,and high levels of corrosion and abrasion.It is widely used in Oil Refineries, petrochemical industries, Fertilizer Plants,Petrochemical plants, Pharmaceutical industries.Material grade for Mechanical seal ring:

GRADE

Main Chemical Component(%)

Bending Stength

(≥N/mm2)

Hardness

(≥HRA)

Density

(g/cm3)

Linear Bulge Modulus

Application guide

WC

CO

Ni

Tic

other

YWN6

94

\

6

\

\

1500

89

14.5-14.9

5.2

Oil,Sewerage,Acid,alkili,Fat,fluidify Hydrocarbon,Strong Alkali With Grain And ETC

YWN8

92

\

8

\

\

1650

88

14.4-14.8

5.3

YWN10

90

\

10

\

\

2100

87

14.5-14.9

5.3

YG6

94

6

\

\

\

1550

89.5

14.7-15.1

5

Oil,Sewerage,soft,Acid,alkili,Fat,fluidify Hydrocarbon,medium With Grain

YG8

92

8

\

\

\

1700

89

14.6-14.9

5.1

YG13

87

13

\

\

\

2400

88

13.9-14.2

6

Gas seal of compressor

YG15

85

15

\

\

\

2500

87

13.9-14.2

6.3

A30

88

2

8

1

1

1700

89

14.0-14.5

6

Oil,Sewerage,soft,Acid,alkili,Fat,fluidify Hydrocarbon,medium With Grain

A10

78

2

10

8

2

1490

89

12.0-12.6

6

Kinds of Tungsten Carbide Strure accords with Chinese Standard YS/T40

Specifications and tolerance of Tungsten Carbide Mechanical Seal : D(mm) d(mm) H(mm) 10~500 2~400 1.5~300 Tolerance can be 0.01mm.Polished Ra 0.1, Ra0.2 ,Ra0.4 ,Also can be supplied at customer's requirements. Our advantage:

1.We can produce almost any of your design efficiently and economically.2.Several grade types for you to choose (Cobalt Bound & Nickel Bound,nickel-bonded grades that provide superior corrosion resistance).3.Exact tolerances ,standard lapped and polished seal faces are flat within 2 light band. tungsten Carbide Mechanical Seal Application:Sealing ring is the main sealing element of rotary joint. The superior wear resistance characteristics of tungsten carbide ringsprovide you the highest pass performance in addition to the very good surface finish.These are used in Oil Refineries,Petrochemical plants,Fertilizer Plants,and Pharmaceutical Industries such as pumps, compressors and agitators.Varioussealing ringswith complicated shape, either blanks or finshed products can be provided.

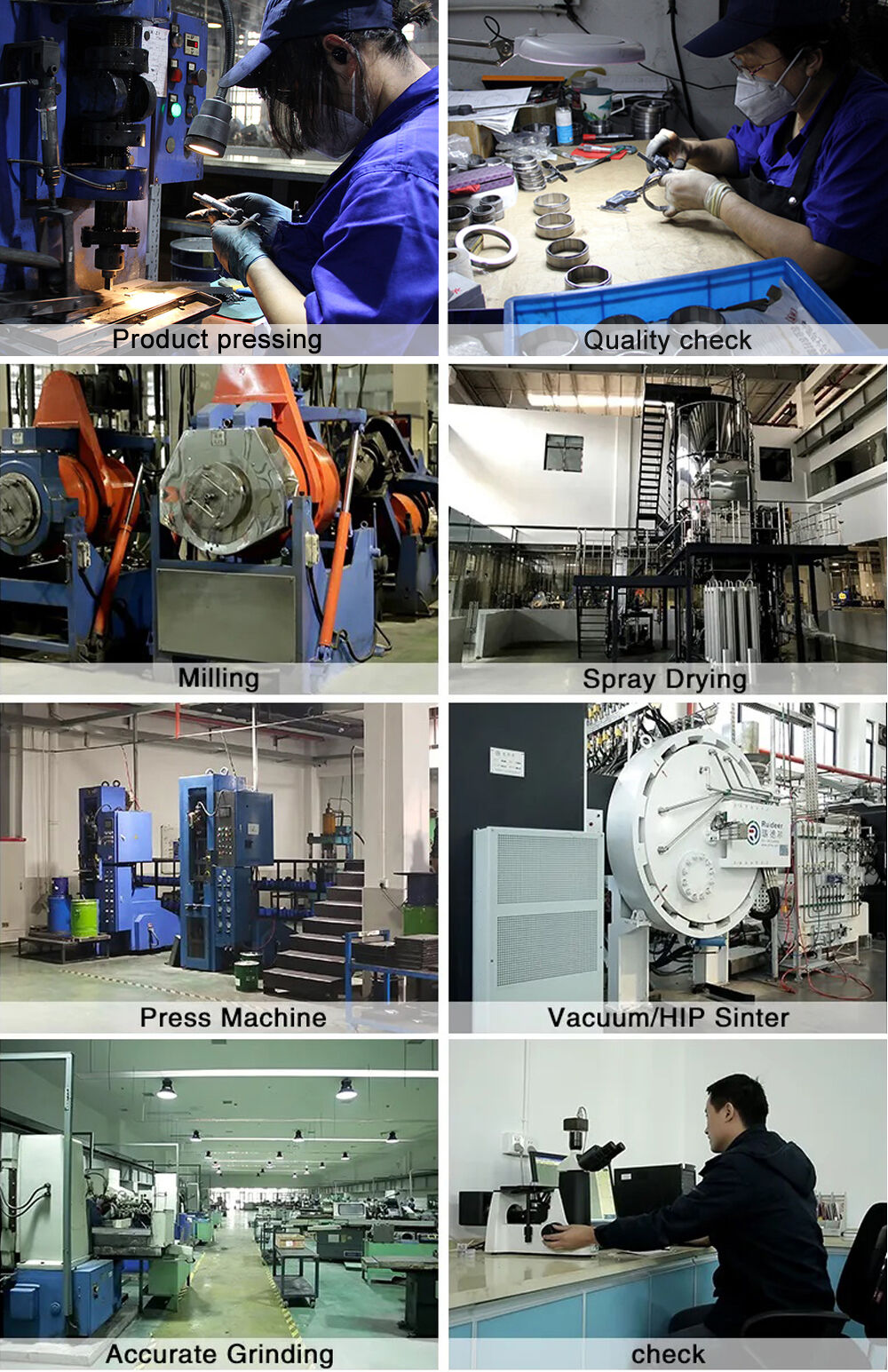

tungsten Carbide Mechanical Seal Application:Sealing ring is the main sealing element of rotary joint. The superior wear resistance characteristics of tungsten carbide ringsprovide you the highest pass performance in addition to the very good surface finish.These are used in Oil Refineries,Petrochemical plants,Fertilizer Plants,and Pharmaceutical Industries such as pumps, compressors and agitators.Varioussealing ringswith complicated shape, either blanks or finshed products can be provided. Quality control:During production process, we adopt the advanced production system and modern technology to monitor all-round quality control form the raw material to final product1. Chemical component analysis of the raw material2. Chemical analysis of the RTP powder3. Physical property testing and metallographic analysis based on trial production4. Testing the tolerance and deformation of the trial products5. Testing the physical properties of every batch of the sintered products6. Flaw detection of the molds and end products7. Testing the sizes, precision and defects of the end productsPrecision Machining:Precision machining is a rigorous and complex process which is widely used in the processing of various mechanical parts. Conventional processing cannot produce high-precision products. More and more customers are requiring high-precision products which makes precision machining as a must-have production capability. Huijin carbide integrates the production and Precision Machining of tungsten carbide products. We equipped with an experienced machining engineering technical team to provide strong technical support for precision machining.There are many kinds of machining methods for carbide precision machining. Such as EDM, slow wire cutting, CNC milling, CNC lathe processing, etc. Huijin carbide specializing in deep processing hard alloy precision molds, wear parts, valve, valve seats, sealing rings and other high precision, thread, special materials, eccentric holes, elbows, special shapes and complex geometric parts.

Quality control:During production process, we adopt the advanced production system and modern technology to monitor all-round quality control form the raw material to final product1. Chemical component analysis of the raw material2. Chemical analysis of the RTP powder3. Physical property testing and metallographic analysis based on trial production4. Testing the tolerance and deformation of the trial products5. Testing the physical properties of every batch of the sintered products6. Flaw detection of the molds and end products7. Testing the sizes, precision and defects of the end productsPrecision Machining:Precision machining is a rigorous and complex process which is widely used in the processing of various mechanical parts. Conventional processing cannot produce high-precision products. More and more customers are requiring high-precision products which makes precision machining as a must-have production capability. Huijin carbide integrates the production and Precision Machining of tungsten carbide products. We equipped with an experienced machining engineering technical team to provide strong technical support for precision machining.There are many kinds of machining methods for carbide precision machining. Such as EDM, slow wire cutting, CNC milling, CNC lathe processing, etc. Huijin carbide specializing in deep processing hard alloy precision molds, wear parts, valve, valve seats, sealing rings and other high precision, thread, special materials, eccentric holes, elbows, special shapes and complex geometric parts. Key words:

Key words:- TC Mechanical seal ring

- YN6 tungsten carbide sealing ring

- OEM seal rings

Previous Page

Previous Page

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!