Tungsten Carbide Roller Rings TC Rings for Industry steel wire rolling

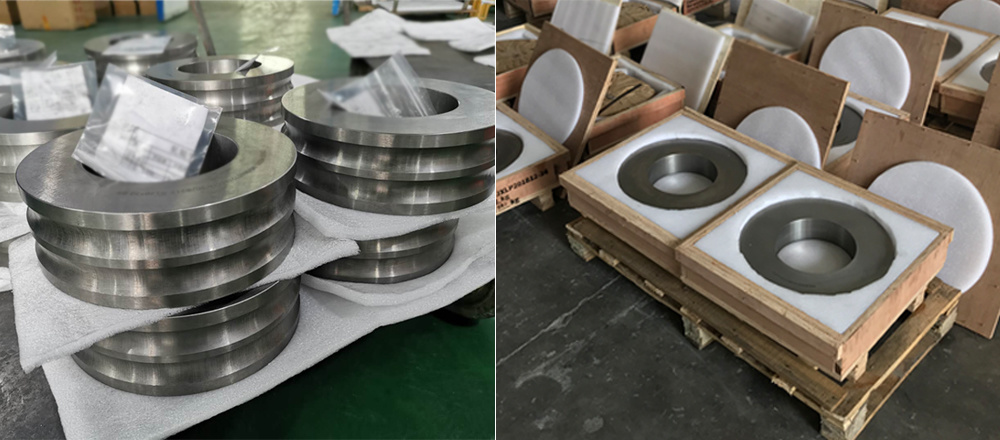

Tungsten Carbide Guide Rollers, also known as carbide rolls, rolling rings, guide rolls, can be customized according to your needs, providing blanks, semi-finished products and finished products.

Key words:

hard metal

Classification:

Tungsten Carbide roller & guide

- 产品描述

-

- Commodity name: Tungsten Carbide Roller Rings TC Rings for Industry steel wire rolling

- Commodity ID: 1310963765452886016

Tungsten Carbide Guide Rollers, also known as carbide rolls, rolling rings, guide rolls, can be customized according to your needs, providing blanks, semi-finished products and finished products.

Product description of tungsten carbide rollerTungsten carbide roller ring is a kind of metallurgical tool which consists of tungsten carbide and cobalt with high hardness and wear resistance. There are ideal for use in applications where strength, durability and longevity are factors. The performance of the tungsten carbide roller is related to the content of the bonding phase metal and the size of the matrix phase--the tungsten carbide powder particle.The different binder content and the corresponding tungsten carbide particle size form different carbide grades. If the content of the metal binder is increased or the particle size of the tungsten carbide is increased, the hardness of the cemented carbide decreases and the toughness increases. Tungsten Carbide (WC) is twice as strong as steel and is similar to corundum in hardness. Tungsten carbide rollers combine superior hardness with resistance to abrasion and wear and they are available in a wide range of sizes. They can also be milled according to the customer's specifications. It has advantage of high wear resistance, long life and high efficiency during the high speed rolling.Material: 100% virgin raw material with submicron and average grain sizeTolerance: strict tolerance extent control, which can reach ±0.01mmGrades: various for choice: Yg15/Ygh30Types: RO Rt Fo Pr

Product description of tungsten carbide rollerTungsten carbide roller ring is a kind of metallurgical tool which consists of tungsten carbide and cobalt with high hardness and wear resistance. There are ideal for use in applications where strength, durability and longevity are factors. The performance of the tungsten carbide roller is related to the content of the bonding phase metal and the size of the matrix phase--the tungsten carbide powder particle.The different binder content and the corresponding tungsten carbide particle size form different carbide grades. If the content of the metal binder is increased or the particle size of the tungsten carbide is increased, the hardness of the cemented carbide decreases and the toughness increases. Tungsten Carbide (WC) is twice as strong as steel and is similar to corundum in hardness. Tungsten carbide rollers combine superior hardness with resistance to abrasion and wear and they are available in a wide range of sizes. They can also be milled according to the customer's specifications. It has advantage of high wear resistance, long life and high efficiency during the high speed rolling.Material: 100% virgin raw material with submicron and average grain sizeTolerance: strict tolerance extent control, which can reach ±0.01mmGrades: various for choice: Yg15/Ygh30Types: RO Rt Fo Pr

Cemented carbide roller used on the stretch reducing mill for bars, thread steel bars and common wire with the durability 10 to 20 times higher compared to common steel roller. The surface quality and the steel bar size accuracy are greatly improved. The cemented carbide roller reduces effectively the production cost and improves the quality.Roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling, Wire Straightening, Wire Guiding etc.Huijin is one of competitive tungsten carbide rolls manufacturers and suppliers, We wish to establish business relation with you.

Cemented carbide roller used on the stretch reducing mill for bars, thread steel bars and common wire with the durability 10 to 20 times higher compared to common steel roller. The surface quality and the steel bar size accuracy are greatly improved. The cemented carbide roller reduces effectively the production cost and improves the quality.Roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling, Wire Straightening, Wire Guiding etc.Huijin is one of competitive tungsten carbide rolls manufacturers and suppliers, We wish to establish business relation with you.

ApplicationTungsten carbide rollers are made by tungsten carbide which have the advantages of high wear resistance, high strength, high heat resistance, thermal conductivity etc. They have been widely used in guides or straightening high speed wire rod, bar, rebar, seamless steel tube etc.Carbide roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling. We can supply them according to the drawings provided by customers.The reference Grade details of Tungsten Carbide Roller for roll guide machine

ApplicationTungsten carbide rollers are made by tungsten carbide which have the advantages of high wear resistance, high strength, high heat resistance, thermal conductivity etc. They have been widely used in guides or straightening high speed wire rod, bar, rebar, seamless steel tube etc.Carbide roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling. We can supply them according to the drawings provided by customers.The reference Grade details of Tungsten Carbide Roller for roll guide machineProperties and applications: Grade Density Co Content TR.S hardness (g/cm3) % (MPa) (HRA) YG15 13.9-14.1 15 ≥2020 ≥86 YGH30 14.02 15 ≥2700 ≥84.9 WIRE RANGE Ø OUTSIDE Ø mm INSIDE Ø mm THICKNESS mm(T) 4-8.5 123 82 15 9-12 123 82 20 4-8.5 125 82 15 9-12 125 82 20 4-8.5 140 90 15 9-12 140 90 20 4-8.5 150 90 15 9-12 150 90 20

Precision MachiningPrecision machining is a rigorous and complex process which is widely used in the processing of various mechanical parts. Conventional processing cannot produce high-precision products. More and more customers are requiring high-precision products which makes precision machining as a must-have production capability. Huijin carbide integrates the production and Precision Machining of tungsten carbide products. We equipped with an experienced machining engineering technical team to provide strong technical support for precision machining.There are many kinds of machining methods for carbide precision machining. Such as EDM, slow wire cutting, CNC milling, CNC lathe processing, etc. Huijin carbide specializing in deep processing hard alloy precision molds, wear parts, valve, valve seats, sealing rings and other high precision, thread, special materials, eccentric holes, elbows, special shapes and complex geometric parts. Key words:

Key words:- Tungsten Carbide Guide Rollers

- Tungsten Carbide Guide

- Customized Tungsten Carbide Guide Rollers

- OEM carbide guide

Previous Page

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!