Tungsten Carbide Ball Bearing

Key words:

hard metal

Classification:

Cemented carbide ball

- 产品描述

-

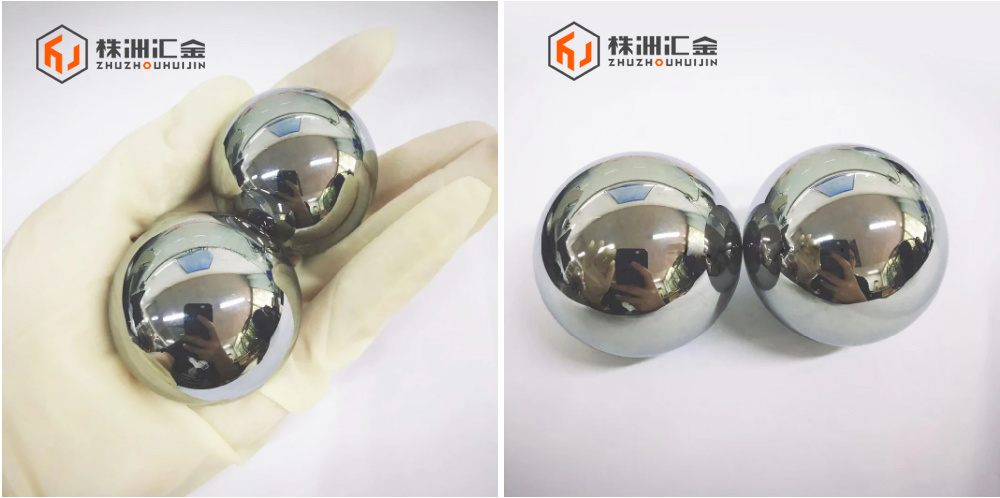

- Commodity name: Tungsten Carbide Ball Bearing

- Commodity ID: 1310963849280245760

TungstenCarbideBalls Madeoftungstencarbide,TungstenCarbideBalls/cementedcarbideball/hardalloyballisalsocalledhardalloyballs. Itisusedforplacesrequiringextremehardnessandresistancetowearandabrasive,ha

Made of tungsten carbide, Tungsten Carbide Balls/cemented carbide ball/hard alloy ball is also called hard alloy balls. It is used for places requiring extreme hardness and resistance towear and abrasive, hard shocks and impacts. They can be used for special valves, flow meters, recirculating balls bearing screws, liner bearing and balls for ball point pens. They are also used for mining, as pivols and points of comparations. What's more, they are also used for measurements or colibrations of holes and measurement checking devices.

Our Company is a leading company in this field for more than 10 years. We produce both standard and non-standard products. Special Drawings/requirements can be accepted and good quality, reasonable price and good service are guaranteed.

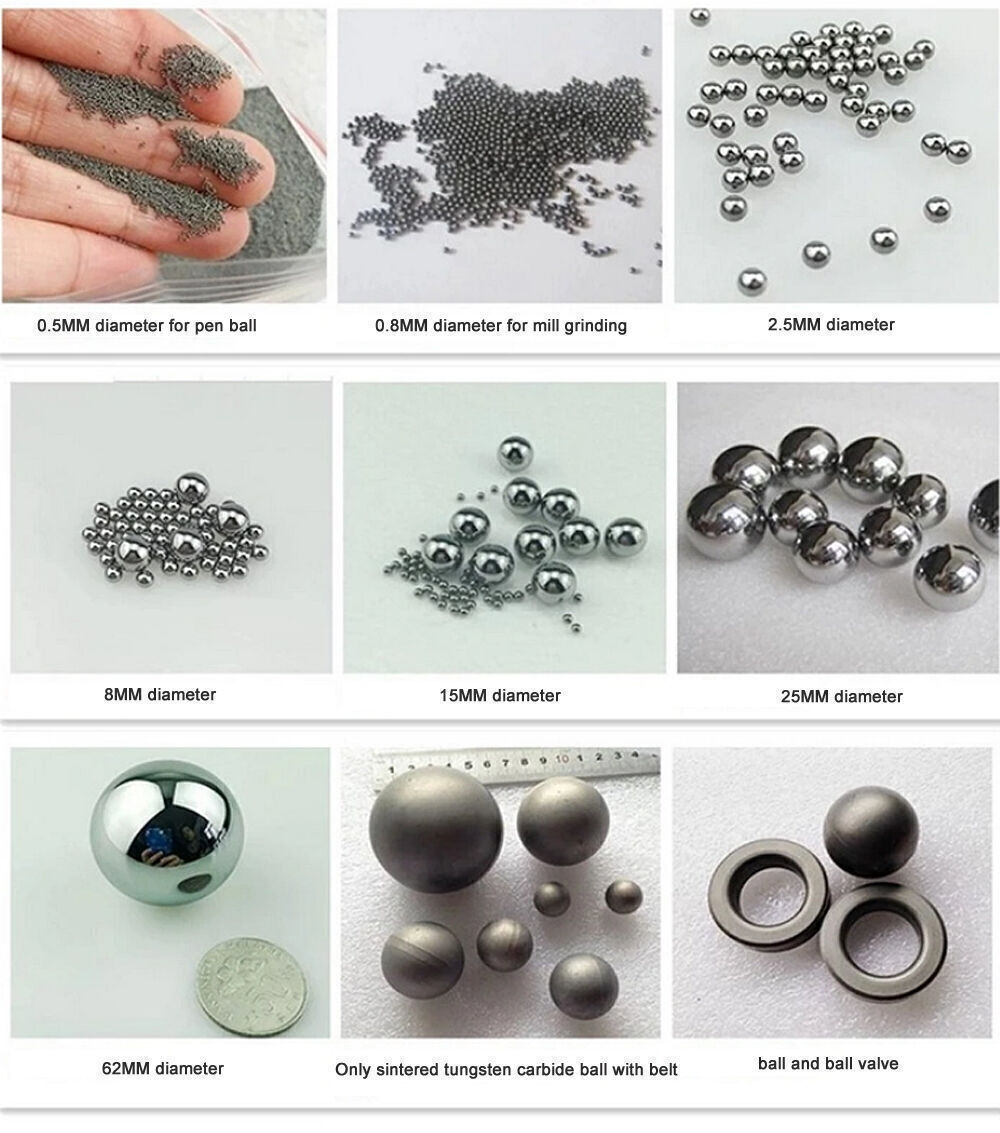

Any size of Tungsten Carbide Balls/cemented carbide ball/hard alloy ball available per customer's drawingsor requrements.

OD Size : 0.3mm to 100mm (Perennial inventory diameter 2-95mm for grade G10 G25 more than 4000 kinds of specifications)Rough and fine ground (European and American standards also available)Rough balls and fine grinding balls of various precision grades are available.The application:The application range of cemented carbide balls is extremely wide, such as: ball screws, inertial navigation systems, precision parts punched and stretched, precision bearings, instruments, meters, pens, sprayers, water pumps, mechanical accessories, sealing valves, brakes High-end industries such as pumps, punching holes, oil fields, hardness measuring instruments, high-quality fishing gear, counterweights, finishing and so on!

OD Size : 0.3mm to 100mm (Perennial inventory diameter 2-95mm for grade G10 G25 more than 4000 kinds of specifications)Rough and fine ground (European and American standards also available)Rough balls and fine grinding balls of various precision grades are available.The application:The application range of cemented carbide balls is extremely wide, such as: ball screws, inertial navigation systems, precision parts punched and stretched, precision bearings, instruments, meters, pens, sprayers, water pumps, mechanical accessories, sealing valves, brakes High-end industries such as pumps, punching holes, oil fields, hardness measuring instruments, high-quality fishing gear, counterweights, finishing and so on!

Tungsten carbide balls

Type

Q-2.3

Q-2.5

Q-2.7

Q-3.3

Q-4.2

Q-5.5

Q-6

Q-8

Q-10

Diameter

2.3

2.5

2.7

3.3

4.2

5.5

6

8

10

Tolerance(mm)

±0.3

±0.3

±0.4

±0.4

±0.5

±0.5

±0.5

±0.5

±0.5

Type

Q-12

Q-20

Q-25

Q-30

Q-35

Q-40

Q-45

Q-50

Q-60

Diameter

12

20

25

30

35

40

45

50

60

Tolerance(mm)

±0.6

±0.6

±0.6

±1.0

±1.0

±1.2

±1.2

±1.6

±1.6

精度级别

直径允许误差

形状圆度误差

表面粗糙度误差

基础直径

批次直径误差

PRECISION CLASS

VARIATION

SPHERICAL

SURFACE

TOLERANCE

LOT VARIATION

G3

0.0762μm

0.0762μm

0.0127μm

±0.762μm

0.127μm

(0.000003″)

(0.000003″)

(0.0000005″)

(±0.0003″)

(0.000003″)

G5

0.127μm

0.127μm

0.02μm

±1.27μm

0.254μm

(0.000005″)

(0.000005″)

(0.0000008″)

(±0.0005″)

(0.00001″)

G10

0.254μm

0.254μm

0.0254μm

±2.54μm

0.508μm

(0.00001″)

(0.00001″)

(0.000001″)

(±0.0001″)

(0.00002″)

G15

0.381μm

0.381μm

0.0254μm

±2.54μm

0.0762μm

(0.000015″)

(0.000015″)

(0.000001″)

(±0.0001″)

(0.00003″)

G16

0.4064μm

0.4064μm

0.0254μm

±2.54μm

0.8128μm

(0.000016″)

(0.000016″)

(0.000001″)

(±0.0001″)

(0.000032″)

G24

0.6096μm

0.6096μm

0.0508μm

±2.54μm

1.2192μm

(0.000024″)

(0.000024″)

(0.000002″)

(±0.00001″)

(0.000048″)

G25

0.635μm

0.635μm

0.0762μm

±2.54μm

1.27μm

(0.000025″)

(0.000025″)

(0.000003″)

(±0.0001″)

(0.00005″)

G48

1.2192μm

1.2192μm

0.0762μm

±0.508μm

2.4384μm

(0.000048″)

(0.000048″)

(0.000003″)

(±0.0002″)

(0.000096″)

G50

1.27μm

1.27μm

0.0762μm

±7.62μm

2.54μm

(0.00005″)

(0.00005″)

(0.000003″)

(±0.0003″)

(0.0001″)

Features and Advantages:Our tungsten carbide ball can be made from 0.5mm to 50mm as required and supply it with a"diameter parallel band" in the 'as sintered' (blank) condition as well as in fully-machined, ground and polished conditions.Best and stable quality at most competitive price.We only use the finest virgin tungsten carbide powder, in this way we can offer you optimum characteristics for your application. Continuous quality control at all intermediate stages of the manufacturing process ensures consistent high quality.Rapid production and delivery time.Factory-direct shipment ensure short delivery time when you need it, 15~25 days.Production ProcessBelow are the production processes of carbide ball valve seat, to ensure high quality, we assureed our customers that:1. All raw materials are tested in terms of density, hardness and T.R.S before use.2. Every piece of product goes through in-process and final inspection.3. Every batch of product can be traced.

Previous Page

Previous Page

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!